In the marine environment, electrical reliability isn’t just a matter of convenience—it’s a critical safety requirement. While standard household wiring might seem like a cost-effective alternative, the unique combination of high humidity, salt-laden air, and constant vibration makes it a recipe for catastrophic failure.

As marine engineers, we strictly utilise multi-strand tinned copper wire to ensure compliance with international safety standards (such as ISO 13297) and to guarantee long-term system integrity.

1. Corrosion Resistance: The Power of Tinning

Bare copper is highly susceptible to oxidation, especially in saline environments. When copper corrodes, it develops a layer of copper oxide (green “verdigris”), which is a poor conductor of electricity and creates resistance.

- The Tin Barrier: Tinned wire features a microscopic layer of tin over every individual strand. This prevents oxidation and ensures the wire remains conductive and easy to solder for the life of the vessel.

- Capillary Action “Wicking”: Moisture can travel up the inside of an untinned wire’s insulation, corroding the entire length from the inside out. Tinned strands significantly slow this degradation process.

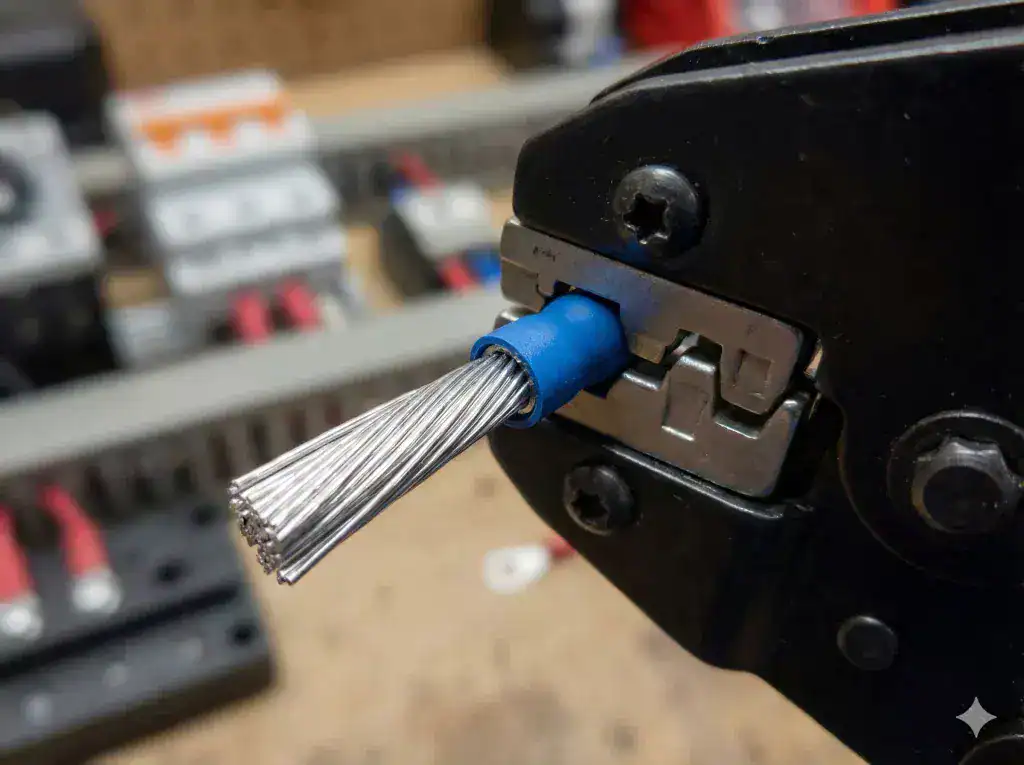

2. Flexibility & Vibration Resistance

Unlike the solid-core wire used in domestic housing, marine systems are under constant mechanical stress from engine vibration and hull movement.

- Work Hardening: Solid-core wire is prone to “work hardening.” Under vibration, it becomes brittle and eventually snaps.

- Multi-Strand Physics: By using hundreds of fine, twisted strands, marine wire remains flexible and can absorb vibration without structural failure.

3. Safety and Standards Compliance

A boat’s electrical system must handle significant current draws while enduring harsh conditions. Using incorrect wiring is a common cause of electrical fires and Boat Safety Scheme (BSS) failures.

- Voltage Drop: Corroded wire increases resistance, leading to a voltage drop. This can cause sensitive electronics (like Diesel Heaters) to throw error codes due to low voltage.

- Fire Prevention: Poor conductivity leads to localised heat buildup at connections. Tinned wire ensures a low-resistance path, minimising the risk of insulation melting and fires.

Engineering Conclusion

Investing in high-quality, marine-grade tinned wire is an engineering necessity, not an optional upgrade. It ensures that your navigation, communication, and heating systems function when you need them most.

Comments are closed.