For boat owners, a Marine LPG Gas Safety Certificate is the definitive proof that an onboard gas system is fit for purpose. Whether you use Liquefied Petroleum Gas (LPG) for cooking, heating, or hot water, ensuring the installation is leak-tight and safe is a critical responsibility.

With the recent release of BS EN ISO 10239:2025, the international standard for LPG systems on small craft has been significantly updated. This update ensures that marine LPG systems are held to the highest possible safety standards to prevent leaks and carbon monoxide incidents.

1. Why Do You Need a Gas Safety Certificate?

While the requirement for a certificate can vary based on your vessel’s use, it is a vital document for three main reasons:

- Insurance Compliance: Most marine insurance providers and marina owners now insist on a valid gas safety record to maintain cover. In the event of an incident, lacking a professional certificate based on current standards could complicate a claim.

- Legal Requirements: If you use your vessel as a primary residence or use the boat for commercial purposes (such as charter or hire), an annual gas safety check is a legal mandate.

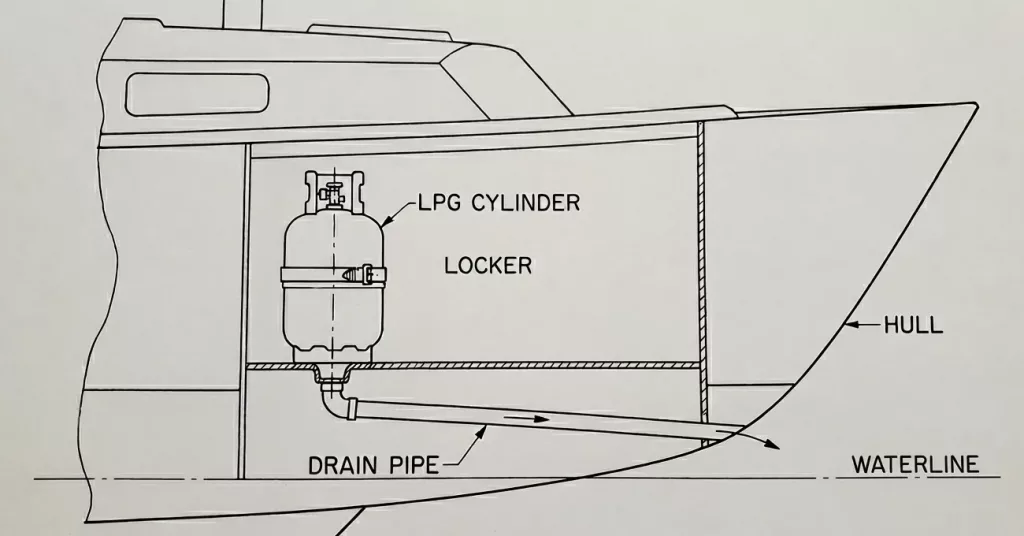

- Safety Assurance: LPG is heavier than air. If a leak occurs, the gas settles in the bilge, creating a high risk of explosion. A certificate confirms that your system has passed a professional pressure test and that all safety devices are functioning.

2. Key Inspection Areas Under BS EN ISO 10239:2025

The updated BS EN ISO 10239:2025 standard governs how your system is inspected. When a qualified engineer visits your boat to issue a certificate, they focus on several high-priority areas:

- Gas Tightness Test: A full pressure test to ensure there are zero leaks in the system.

- Cylinder Storage: Verification that lockers are gas-tight to the hull and drain overboard.

- Appliance Safety: Checking that all burners have Flame Supervision Devices (FSDs).

- Ventilation: Calculation of fixed ventilation to ensure safe combustion and CO prevention.

3. The Impact of the 2025 Update

The BS EN ISO 10239:2025 update introduces stricter protocols for the durability of components in harsh marine environments and the accessibility of shut-off valves. If you are upgrading your galley or installing a new heating system, ensuring the work meets the 2025 specifications is vital for your safety and compliance.

One notable change involves unattended appliances, such as gas-powered refrigerators. The new standard requires even more rigorous ventilation checks to prevent the silent danger of Carbon Monoxide (CO) poisoning in confined cabin spaces. A compliant LPG system is the basis for passing a Boat Safety Scheme (BSS) examination.

Engineering Conclusion

Adhering to the BS EN ISO 10239:2025 standard is not just about ticking a box for your insurance; it is about ensuring the safety of everyone on board. If your current setup hasn’t been inspected recently, booking a professional audit is the best way to ensure long-term peace of mind.

Comments are closed.