The Single Most Critical Link in Your Gas System

It is easy to dismiss an LPG gas hose as just a simple rubber tube. In reality, it is the single most critical safety link in your entire marine gas system. This “artery” is responsible for carrying volatile, pressurised fuel from your cylinders to your fixed pipework or appliances.

As we move into 2026, UK regulations regarding gas safety on inland and coastal vessels have never been stricter. Using the wrong type of hose, or one that has exceeded its service life, introduces severe risks of fire and explosion that are entirely avoidable with professional oversight.

For quotes and bookings regarding LPG appliance safety surveys, please call or email us here.

Building a safe system? Read our guide on Marine LPG Cylinder Regulators and OPSO Devices .

1. Why Marine LPG Hoses Require Specialised Engineering

You can never substitute a dedicated LPG hose with generic tubing or water hoses. A marine LPG hose must withstand constant internal pressure while fighting off chemical degradation from the compounds in propane and butane. Furthermore, it must survive “environmental abuse” like UV light, extreme temperature shifts, and physical abrasion in the tight confines of a boat locker.

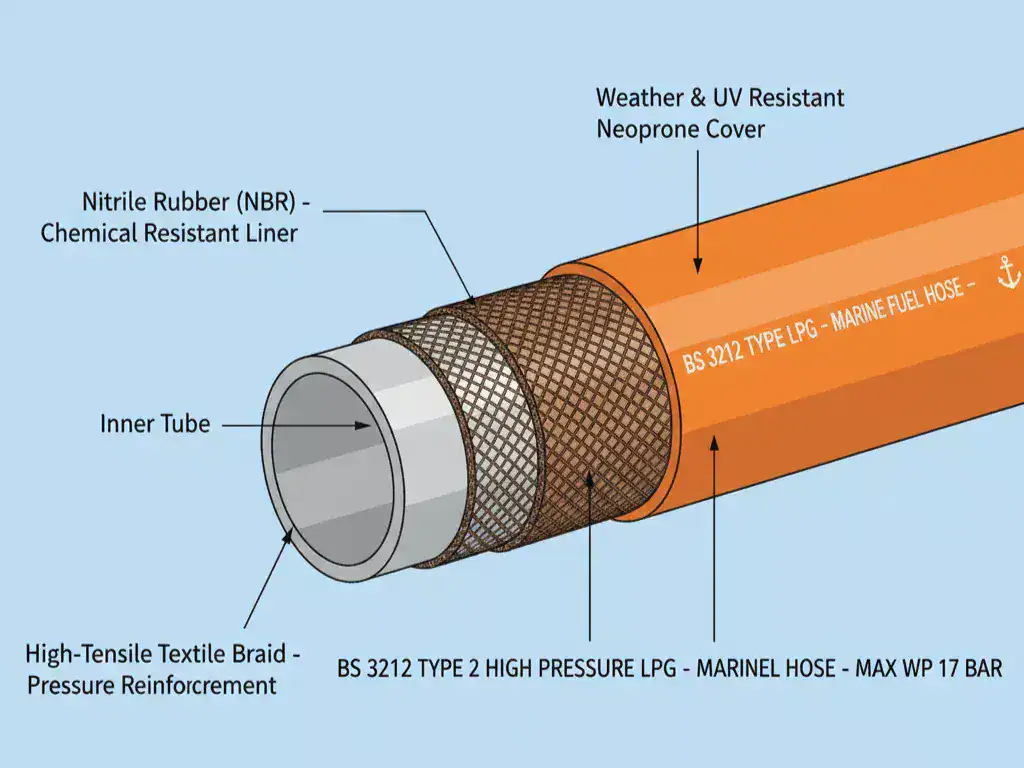

Built-in Layers for Maximum Security

A compliant marine hose is a multi-layered piece of safety equipment:

- The Inner Tube: Typically made from specialised nitrile (NBR) or neoprene, this layer is chemically resistant to ensure the gas does not permeate the rubber.

- The Reinforcement: A high-tensile textile braid (or steel in some high-pressure variants) acts as the “muscle,” allowing the hose to handle high pressure without swelling.

- The Outer Cover: A durable, weather-resistant bodyguard that fends off sunlight and physical scuffs.

2. Decoding the UK Standards: BS 3212

In the UK, any hose used for LPG must comply with BS 3212. This certification is your absolute guarantee that the hose has been rigorously tested for pressure resistance, flexibility, and material stability.

High Pressure vs. Low Pressure

It is vital to understand the difference between the two primary types of hoses used on boats:

- Type 1 (Low Pressure): Designed for use downstream of the regulator (low-pressure side).

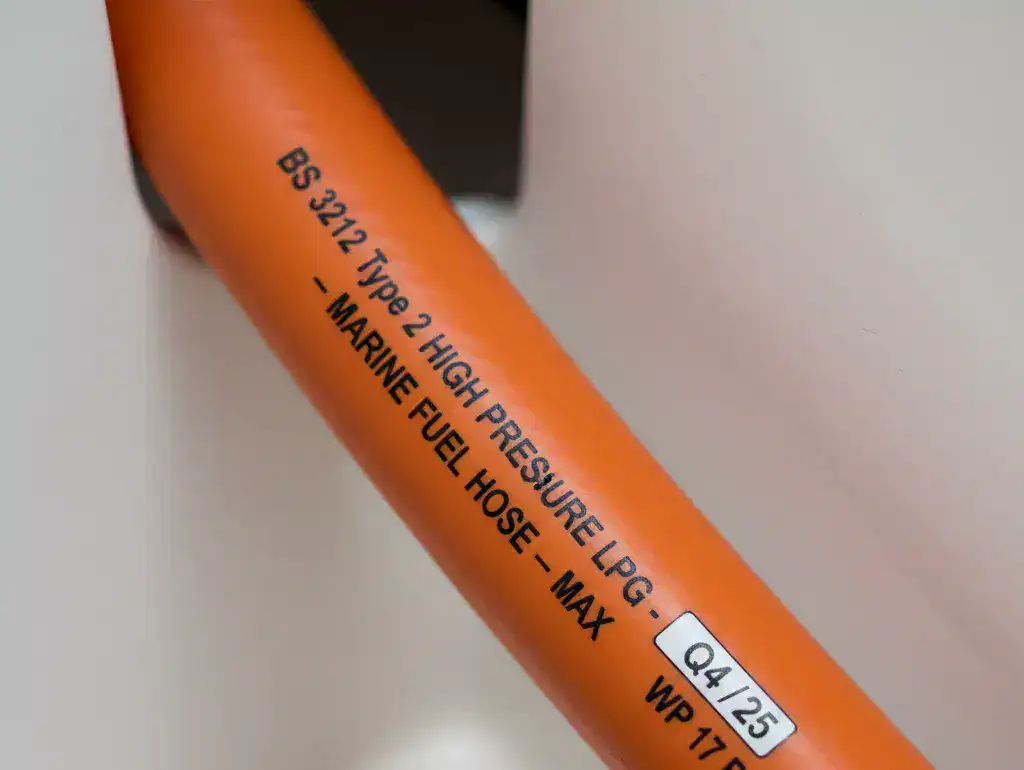

- Type 2 (High Pressure): Mandatory for the “pigtail” connection between the cylinder and the regulator. Under current safety rules, these must be marked as ‘High Pressure LPG’.

3. The 5-Year Replacement Rule

This is the most critical part of your maintenance routine: LPG hoses must be replaced every five years, regardless of how good they look. Over time, the materials undergo invisible degradation.

The manufacturing date is always printed on the hose (often as a quarter and year, e.g., Q2 24). If your hose is approaching its fifth birthday, or if it lacks a legible date stamp, it is a Boat Safety Scheme (BSS) requirement to replace it immediately.

4. Professional Installation and OFTEC Certification

While you can change a gas cylinder yourself, any work on a fixed installation is a legal responsibility that must be handled by a professional. In the UK, this falls under the Gas Safety (Installation and Use) Regulations 1998.

As OFTEC and Gas Safe registered engineers, we ensure that:

- Hose lengths are kept as short as practically possible to minimise risk.

- Connections are secured with proper swaged fittings or certified hose clips—never generic jubilee clips, which can cut into the rubber and cause leaks.

- The entire system is pressure-tested for even the smallest leaks before certification.

5. Your 2026 LPG Hose Safety Checklist

Use this table as a routine inspection guide to spot hazards before they become emergencies.

| Check/Attribute | Why It Matters | What to Look For |

| Date Stamp | Hoses have a limited 5-year lifespan. | Replace if past 5 years from the date printed on the hose. |

| Cracks/Splits | Even tiny cracks indicate perished rubber. | Bend the hose gently; look for any “crazing” or surface splits. |

| Bulges/Blisters | Signals an internal structural failure. | Feel for soft spots or bubbles along the length of the tube. |

| Kinks/Damage | Physical damage creates a high-pressure weak spot. | Ensure smooth curves; no sharp bends or rubbing against edges. |

| Connections | The most common source of undetected leaks. | Ensure fittings are secure and swaged correctly; check for smell/bubbles. |

Conclusion: Don’t Take the Risk

A few pounds spent on a new, high-quality LPG hose can be the difference between a safe season on the water and a catastrophic failure. If you are unsure of the age or condition of your gas system, a professional survey is the only way to gain true peace of mind.

Comments are closed.