Securing a certified marine professional for your vessel’s LPG system is a critical step for any owner. Unlike a stationary home, a boat is a dynamic environment where constant vibration, high humidity, and hull movement put unique stresses on gas pipework and appliances. Only a technician with specific marine-grade training can ensure that your setup is safe, legal, and reliable enough to withstand the rigours of life on the cut. Understanding the evolution of waterways heritage helps put into perspective why modern safety standards are so rigorous compared to the industrial era of the network.

Why Marine Expertise is Non-Negotiable

A standard domestic gas fitter is trained for environments that stay still. On a boat, the stakes are significantly higher because Liquefied Petroleum Gas (LPG) is heavier than air; in the event of a leak, it doesn’t dissipate—it sinks and pools in the bilges, creating an invisible and highly explosive hazard.

Specialist engineers understand the complexities of “room-sealed” appliances and the strict ventilation requirements mandated by the Boat Safety Scheme (BSS). Without this specific knowledge, an installer might inadvertently create a “ticking time bomb” by using incorrect materials or failing to account for unique airflow patterns within a confined hull.

The Dangers of Substandard Work

- Explosion Risk: Pooling gas in low spots can be ignited by a single battery spark.

- Carbon Monoxide: Poorly fitted flues are a leading cause of CO buildup. You can learn more about how to prevent carbon monoxide poisoning in our detailed guide.

Decoding Engineer Qualifications

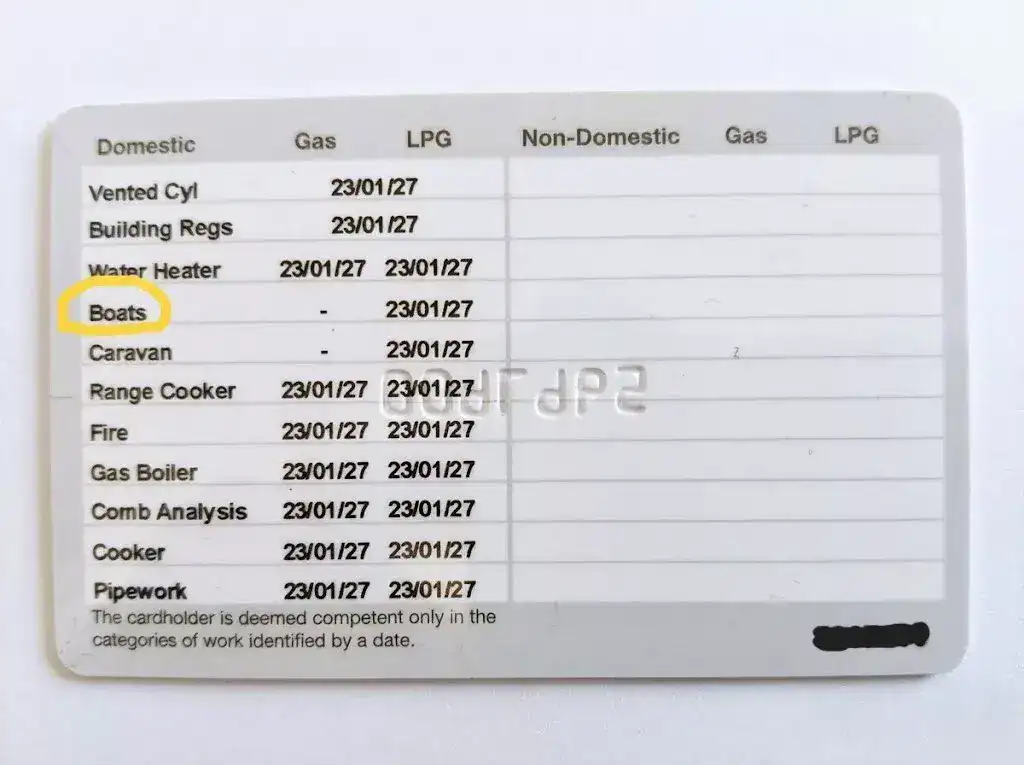

When you search for an engineer, their credentials are your only guarantee of safety. In the UK, anyone working on gas must be registered on the official Gas Safe Register. However, a standard registration for houses is not sufficient for work on the water.

The “Boats” Specialism

Your engineer’s Gas Safe ID card must explicitly list ‘LPG’ and ‘Boats’ on the reverse side. If they do not hold this specific marine specialism, they are legally prohibited from working on your vessel. This qualification ensures they understand the specific British Standards, such as BS EN ISO 10239, that apply to small craft gas systems.

Safety/Regulatory: OFTEC and Canal & River Trust (CRT)

While the Gas Safe Register covers LPG, many boats utilise multiple fuel sources to remain comfortable year-round. It is common to see a technician who also holds OFTEC registration for diesel-fired systems or HETAS for solid fuel. Additionally, the Canal & River Trust (CRT) provides the overarching regulatory framework for UK inland waterways, requiring that all gas installations pass a Boat Safety Scheme inspection.

How to Properly Vet Your Engineer

Confirming legal qualifications is the first step, but a professional should also be transparent about their business practices.

- Request Proof of Insurance: A reputable marine engineer will carry public liability insurance specifically covering work on vessels.

- Ask for a Written Quote: Avoid verbal estimates; a detailed quote should break down labour and parts, reflecting a professional assessment of the job.

- Check References: Word of mouth in the boating community is invaluable; look for recommendations at local marinas or check for examples of professional boat LPG gas installations before booking.

[IMAGE PLACEHOLDER 3: A professional, tidy LPG installation in a narrowboat galley, showing clean copper pipework, an easily accessible isolation valve, and proper bulkhead fittings.]

BSS Examiner vs. Boat Gas Engineer

There is often confusion between these two roles. A Boat Safety Scheme (BSS) Examiner is an inspector who checks your boat against a checklist to ensure it meets minimum safety requirements every four years. They generally do not carry out repairs.

If an examiner flags a leak or a non-compliant fitting during an inspection, your next call must be to a qualified engineer to perform the actual remedial work. The examiner identifies the problem; the engineer provides the solution. You can view more about boat LPG certificates in our services section.

Managing Multi-Fuel Systems

Many boat owners prefer a holistic approach, using LPG for cooking and a canal boat central heating system powered by diesel or solid fuel. A versatile engineer who understands how these systems interact—for instance, ensuring a diesel heater exhaust isn’t too close to an LPG locker vent—is a significant asset for any boat owner.

Comments are closed.