For year-round boating, a reliable diesel boat heating system is a necessity for hull preservation and crew comfort. Unlike domestic heating, marine systems must contend with high vibration, salt-air corrosion, and strict safety regulations regarding exhaust and fuel management.

Choosing the right system requires understanding the balance between fuel consumption, electrical draw, and the specific insulation properties of your vessel.

1. Types of Marine Diesel Heaters

There are two primary ways to heat a vessel using diesel fuel:

- Air Heaters (Blown Air): Systems like the Autoterm Air or Eberspächer Airtronic heat air via a heat exchanger and distribute it through ducting. They provide near-instant heat and are highly effective at reducing cabin humidity.

- Hydronic (Water) Heaters: These heat a coolant fluid that circulates through radiators or matrix heaters. While they take longer to warm the cabin, they can also provide domestic hot water and offer a quieter operation for overnight use.

2. Installation Standards and BSS Compliance

As a BSS Examiner, I focus on installation details that ensure long-term safety and compliance with the Boat Safety Scheme. Critical areas include:

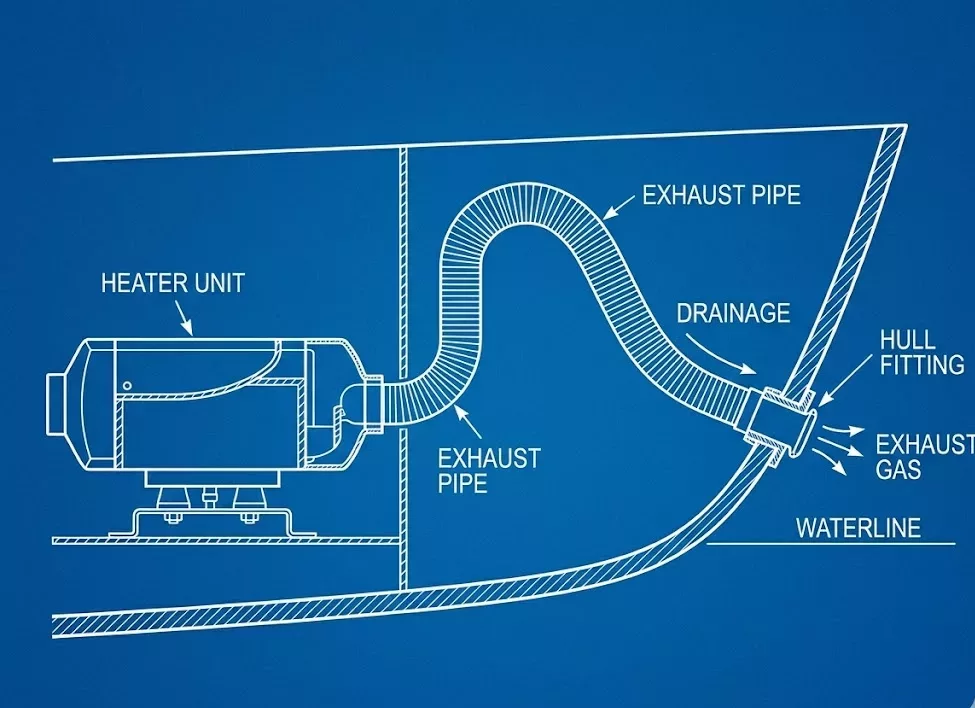

- Exhaust Routing: Exhaust temperatures can exceed 300°C. High-quality lagging and a stainless steel skin fitting are essential to prevent fire risks.

- Fuel System Integrity: Fuel lines must be fire-resistant and fitted with a localised shut-off valve. Avoid sharing engine fuel lines to prevent airlocks and starvation issues.

- Combustion Air: Air intakes must be positioned away from the engine or exhaust fumes to prevent Carbon Monoxide (CO) from being drawn into the living spaces.

3. Brand Comparison: Eberspächer, Webasto, and Autoterm

Selecting the right unit depends on your vessel type and typical usage:

| Feature | Eberspächer Airtronic | Webasto Air Top | Autoterm (Planar) |

| Primary Strength | Advanced digital diagnostics | Extremely quiet operation | Excellent reliability and value |

| Best For | Modern yachts with complex DC systems | High-end cruisers | Narrowboats and live-aboards |

| Parts Availability | Widely available | Global support network | Strong UK support and DIY-friendly |

4. Maintenance and Longevity

To prevent “carboning up” and ensure your heater starts every time:

- Full Power Cycles: Once a month, run the heater on maximum power for at least 30 minutes to burn off internal carbon deposits.

- Fuel Quality: Use clean, high-grade diesel. If using red diesel, a dedicated fuel conditioner is recommended to improve combustion efficiency.

- Summer Maintenance: Do not leave the unit dormant during warmer months. Running the heater for 15 minutes once a month prevents the fuel pump from seizing.

Engineering Conclusion

A professionally installed diesel boat heating system transforms the usability of your vessel. By adhering to BSS standards and choosing proven components, you ensure a safe, warm, and dry environment regardless of the weather outside.