Maintaining your boat’s diesel appliances is about more than just “checking it works.” In the marine environment, salt air, red diesel, and vibration create unique challenges that domestic systems never face.

Whether you are running a forced-draft heater, a Refleks stove, or a high-output pressure jet boiler, regular professional maintenance is the difference between a cosy winter and a dangerous, costly failure.

Why Marine Diesel Servicing is Non-Negotiable

Modern diesel appliances are highly efficient but have narrow tolerances. Professional servicing focuses on three core pillars:

- Safety First: We inspect fuel lines, flues, and combustion chambers for signs of fatigue or Carbon Monoxide (CO) leakage.

- Fuel Economy: Carbon buildup (coking) reduces heat transfer. A clean burner can reduce fuel consumption by up to 15%.

- Longevity: Preventing “diesel bug” and soot accumulation avoids the need for premature, expensive unit replacements.

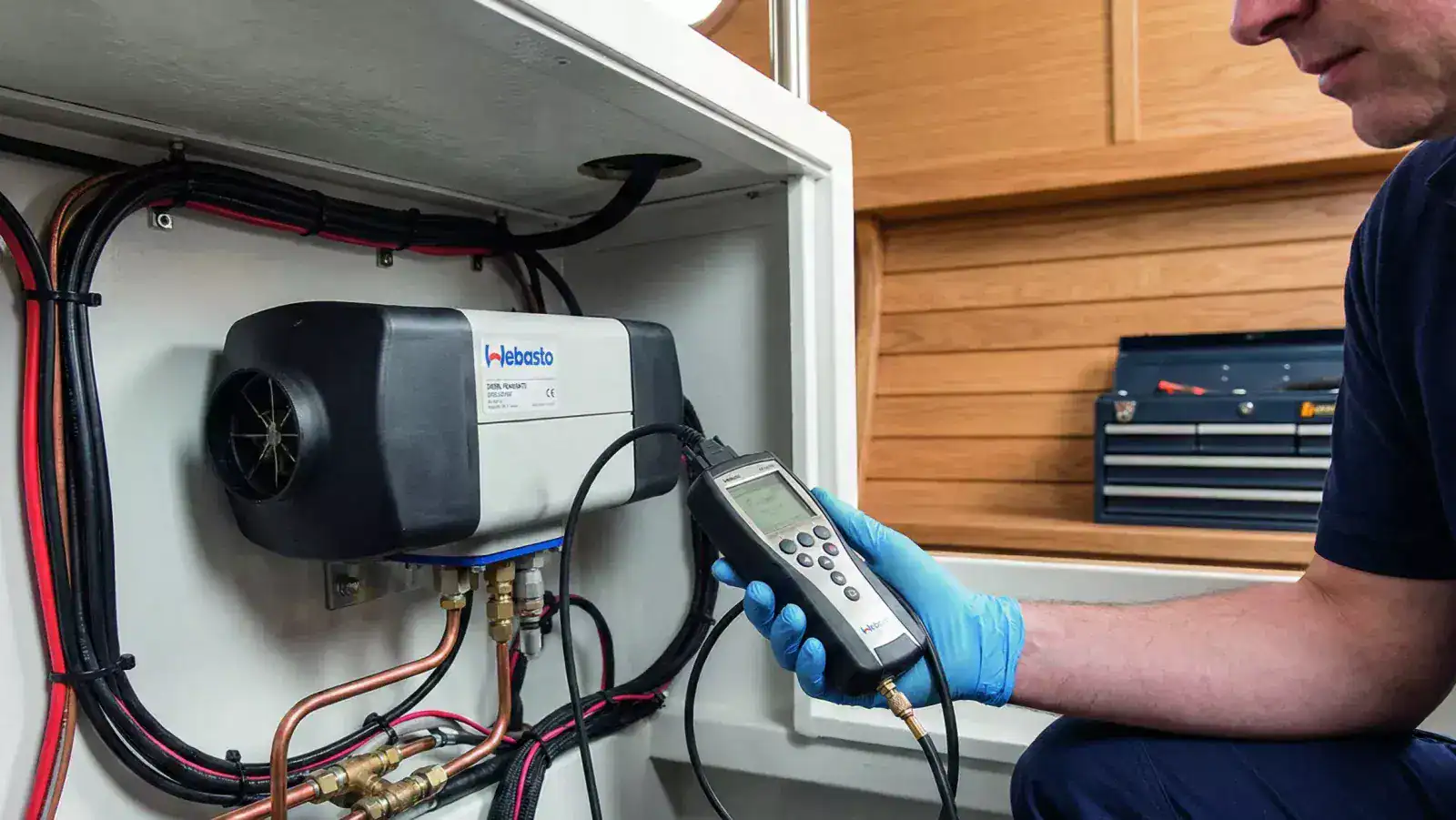

1. Forced Draft Diesel Heaters (Eberspächer, Webasto, Autoterm)

These units are the workhorses of the narrowboat world. Because they “pulse” fuel, they are prone to carbonisation

if not run at full temperature regularly.

Our Service Includes:

- Full disassembly and heat exchanger decoke.

- Glow Pin & Screen Replacement: We replace the burner screen to ensure reliable ignition every time.

- Diagnostic Check: Clearing stored error codes and checking fan speed parameters to prevent mid-winter lockouts.

2. Vaporising Burner Stoves & Cookers (Refleks, Bubble, Dickinson)

Commonly found on traditional narrowboats and liveaboards, these gravity-fed systems rely on a clean “pot” and a perfectly calibrated flow of fuel.

Key Maintenance Areas:

- Toby Valve Calibration: We dial in your metering valve to ensure your “low” and “high” settings are safe and efficient.

- Burner Pot Cleaning: Removing the hard carbon “clinker” that builds up at the base of the pot.

- Flue Sweeping: Essential for vaporising stoves to maintain the correct “draw” and prevent back-filling the cabin with fumes.

3. Pressure Jet-Fired Boilers

For larger vessels and widebeams with full central heating, pressure jet boilers (like Kabola or Heritage) require a level of precision similar to a home oil boiler, but adapted for sea-going conditions.

What We Do:

- Nozzle Replacement: The injector nozzle is a wear item; we replace it annually to ensure a perfect spray pattern.

- Photocell Cleaning: Ensuring the flame sensor is clear to prevent unnecessary “lockouts.”

- System Flushing: We recommend replacing coolant every 3–5 years to prevent internal corrosion of the back boiler system.

Compliance and Safety Standards

All our work is carried out to the highest industry standards. If you are preparing for your Boat Safety Scheme (BSS) examination, having a recent service record for your diesel appliances is a major point of reassurance for your examiner.

We also provide Gas & Diesel Safety Certificates for residential boats and commercial hire craft.

Ready to ensure your boat is winter-ready?

Don’t wait for a cold snap to find out your heater is locked out.

Comments are closed.